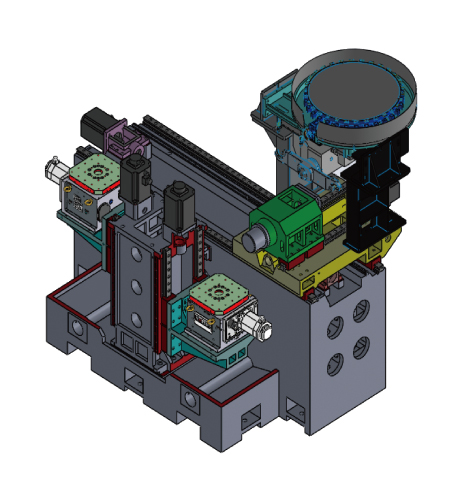

Horizontal Machining Center

Unique design of the structure, minimize the time of processing and reduce the tolerance of table.

Main frame is made of Meehanite casting for superior rigidity.

All axes are mounted with high speed, heavy duty PMI, SP class, roller type linear guide ways.

Steel telescopic ways cover on axes protecting ways and ballscrews from dust.

Fully enclosed splash guard to ensure the security during operation.

Structures & FeaturesRigidityStructure |

Patent certification |

| Auto lubrication system (Grease) |

| The special Automatic Tool Changing System make the processing more efficiency |

| All connectives with scraping |

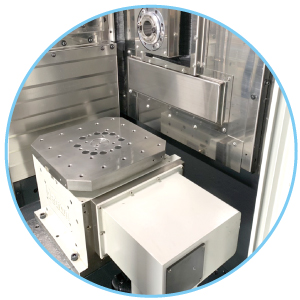

| The independent table make the positioning of the long-ternprocessing more precise, stable |

| The independent table make the positioning of the long-ternprocessing more precise, stable |

| All connectives with scraping |

| 45mm PMI (SP class) roller type linear guide ways and heavy duty slideblocks |

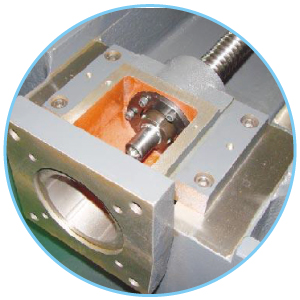

| Nut screw coolant device in the ball-screw |

Model | U2-32H |

| Travel | |

| XA / XB-axis travel | 320 / 320 mm |

| Y-axis travel (A / B zone) | 320 / 320 mm |

| Z-axis travel | 320 mm |

| Spindle center to table surface | 85-405 mm |

| Spindle nose to table center | 40-360 mm |

| Table | |

| Table working surface | 320 × 320 mm |

| Max loading capacity | 200 kg |

| Table indexing | 0.001 |

| Number of tables | 2 |

| Time of changing table | 3 sec |

| Spindle | |

| Spindle speed (RPM) | 12,000 rpm (15,000 rpm Opt.) |

| Spindle transmission | Direct Type |

| Spindle taper hole | BT-40 (BBT-40 Opt.) |

| Feedrate | |

| Rapid traverse | 24 M / min |

| Max. cutting rate | 10 M / min |

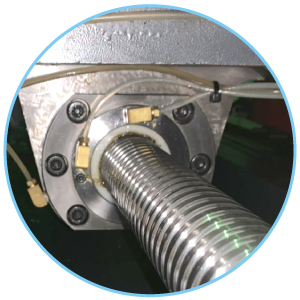

| Size of the linear guideway | PMI SP Class Roller type 45mm |

| X1 /X2 / Y / Z ballscrews size | Ø40 / Ø40 / Ø50 / Ø40 |

| A.T.C. | |

| Tool storing capacity | 30 Tools (40 Tools Opt.) |

| Type | Arm Type |

| Max. tool dimension | 75 mm |

| Max. tool length | 180 mm |

| Max. tool weight | 7 kg |

| Motor | |

| Spindle drive motor | 7.5 / 11 kw |

| Servor drive motor(X1/X2/Y/Z/A/B) | 4.0 / 4.0 / 4.0 / 3.0 / 1.6 / 1.6 kw |

| Power consumption | 35 KVA |

| Machine Size | |

| Dimension (L x W x H) | 3050 × 2250 × 2200 mm |

| Weight | 8800 kg |

CNC Mitsubishi M80A/ Fanuc 0iMF |

Fully enclosed splash guard |

All axes guide-way cover |

Nut screw coolant device in the ball-screw |

Spindle cooling system |

Chip conveyor with cart |

Auto lubrication system(Grease) |

Work lamp, Alarm lamp, Tool box |

Leveling bolts and pad |

Portable M.P.G |

Auto power off (M30) |

Machine manuals |

CNC controller Mitsubishi / Fanuc / Siemens / Heidenhain |

Tool Length Measurement |

Workpiece Measurement |

Linear scale feedback |

Coolant through spindle |

Oil Demister system |

Air cooled heat exchanger |

40 ATC (Arm Type) |

Transformer 220V-380V-440V |